-

-

-

- Home

- Site Index

- about FMT

- Food Processing

- Further Processing

- Thermal Processing

- Contact

- Search

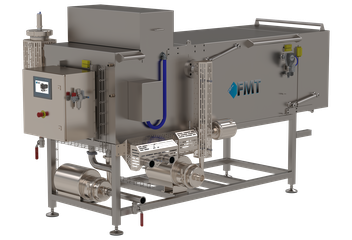

FMT frying solutions enable full control of the (pre-)frying process, including optimal cooking control and oil quality management. FMT offers hot oil open systems and water/oil-based machines. Our innovative machines come with adjustable and energy-efficient heating systems and different continuous filtration systems for lower production costs and higher product quality. The FMT frying program also includes oil storage tanks and paper belt filters.

FMT Paper filter installation removes fine solid particles from the frying oil (oil polishing). The oil is pumped directly from the frying unit or through a rotating filter onto a conveyer belt with the filtering paper. The oil runs through the paper, the particles stay behind. The purified and therefore healthier oil is pumped back into the frying unit. The installation automatically controls oil levels and renews filter paper when its filtering powers lessen. Saturated paper is automatically transported, folded and stored into a waste container. The installation can be used with different filter paper sizes and is mounted on a movable frame. Like all FMT machines the paper filter is built from first class materials for lesser maintenance costs and designed for optimal safety and easy cleaning.

Summary of benefits

• Prolongs the oil’s life: less oil change

• Fully automatic and mess-free oil recycling

• Double-walled design for greater safety

• Hinged lid and removable belt for easy cleaning and maintenance

• Mounted on a wheelable frame for easy positioning

Or contact us directly at

Uilenwaard 48

5236 WB 's-Hertogenbosch

The Netherlands

Phone: +31 (0)73 5114436

E-mail: info@fmt.nl