-

-

-

- Home

- Site Index

- about FMT

- Food Processing

- Further Processing

- Thermal Processing

- Contact

- Search

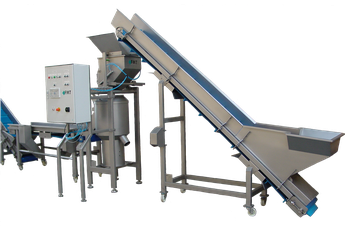

FMT offers complete production/processing lines for fresh potatoes with accessories. These machines come standard with many adjustable features for rapid processing of the wide variety of base materials. The machines are also extra sturdy to reduce wear and therefore downtime as much as possible.

The FMT peeling machines are suitable for the continuous peeling of root products such as potatoes, carrots, kohlrabi, red beets, celariac etc. Continuous roller peeler as well as batch peelers both with abrasive surface in which the skin of the potato is removed mechanically. Potatoes supply by a conveyor.

The continuous peelers have rollers who are constructed in a drum in which a screw transport the product to the discharge opening. The drum construction has the advantage that the product is running with a low speed. The waste can be discharged underneath the machine with our without water. The drives of the drum, rollers and screw are variable by frequency control converters.

The abrasive surface of the continous peelers can peel off ca.800 kg./hour. Peeling with a waste of ca. 25% gives an input of 3200 kg./hour if the grain on the rollers is in a good condition. All depending on the skin and quality of the peeled product.

The continuous peeling machines are easy to clean and to maintenance. On both side you can open the covers for cleaning and maintenance. The whole machine in accordance with CE regulations.

A control panel can be supplied, which controls the number of revolutions of the peeling rollers and the transport auger can be adjusted (independent of each other). The desired peeling result can be adapted optimally to every type of product.

Or contact us directly at

Uilenwaard 48

5236 WB 's-Hertogenbosch

The Netherlands

Phone: +31 (0)73 5114436

E-mail: info@fmt.nl