-

-

-

- Home

- Site Index

- about FMT

- Food Processing

- Further Processing

- Thermal Processing

- Contact

- Search

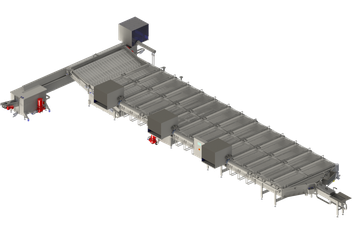

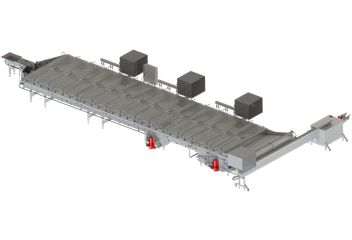

During packaging the product temperature is approximately 160° C. Flat films normally melt at this temperature. The FMT cooling system cools the flat films down already during the filling process. Finished hot melt packs are then fed into a (patented) cooling bath. The FMT system cools down the products to a core temperature of e.g. 37°C. After that the packages can be packed into cardboard boxes and/or palletized.

The FMT advanced cooling system for cooling of adhesive products (Hot Melt) after packaging.

The main advantages and features of the system are:

• Improved product quality with higher yield.

• Increased energy efficiency and reduced total operating costs.

• Designed for very even and consistent cooling.

• Program control for quick changeover between processes.

• Various cooling lengths and widths available.

Or contact us directly at

Uilenwaard 48

5236 WB 's-Hertogenbosch

The Netherlands

Phone: +31 (0)73 5114436

E-mail: info@fmt.nl